In addition to filters, other spare parts such as the Flyash hose 10 bar are equally indispensable in construction machinery. Flyash hoses play a critical role in the transportation of abrasive materials like fly ash, ensuring a steady and uninterrupted flow during concrete mixing and placement processes. With a durable construction designed to withstand high-pressure applications, Flyash hoses help to optimize the efficiency of construction operations, reducing the risk of equipment malfunctions and downtime.

In the construction machinery, the significance of spare parts cannot be overstated, with each component playing a crucial role in ensuring the seamless operation of equipment. Among these vital components, filters for Putzmeister concrete pump stand out as essential elements that contribute to the efficient functioning of the machinery. Filters serve to remove contaminants and impurities from the hydraulic system, preventing damage to sensitive components and ensuring optimal performance. By maintaining clean and well-functioning filters onsite, construction teams can avoid costly downtime and delays, allowing projects to progress smoothly and efficiently.

Another

essential spare part commonly used in construction machinery is the concrete

hose 85 bar. These high-pressure hoses are specifically designed for the

transportation of concrete from the mixer to the desired placement location on

the construction site. With their robust construction and high tensile

strength, concrete hoses can withstand the abrasive nature of concrete mixtures

and the rigorous demands of construction applications. By keeping a ready

inventory of concrete hoses onsite, construction teams can ensure smooth and

efficient concrete pouring operations, minimizing the risk of delays and

project setbacks.

Similarly,

cement hoses 10 bar play a vital role in the efficient operation of

construction machinery, particularly in cement mixing and pumping applications.

These hoses are designed to handle the abrasive properties of cement and other

abrasive materials, ensuring a reliable and consistent flow during the

construction process. By keeping an inventory of cement hoses readily available

onsite, construction teams can mitigate the risk of equipment failures and

downtime, allowing for uninterrupted progress on construction projects.

Finding

dealers or suppliers who can provide a comprehensive range of spare parts under

one roof and manage a well-maintained inventory is essential for construction

companies looking to streamline their operations and minimize downtime. One

effective approach is to conduct thorough research and compile a list of

reputable dealers or suppliers known for their expertise in construction

machinery spare parts. Online platforms, industry forums, and recommendations from

peers can serve as valuable resources in identifying potential suppliers.

After

compiling a list of potential dealers or suppliers, it becomes imperative to

assess each option meticulously, considering factors like the breadth of spare

parts available, product quality, pricing, delivery efficiency and customer

support. Direct engagement, such as visiting dealerships or scheduling meetings

with their representatives, offers invaluable insights into their inventory

management protocols and overall dependability as a supplier. This hands-on

approach ensures informed decision-making, leading to partnerships that align

closely with the requirements and standards of the construction operation.

An

additional critical factor to contemplate when choosing a dealer or supplier is

their proficiency in inventory management. An adept supplier with an efficient

inventory management system guarantees the prompt availability of spare parts,

mitigating the potential for delays and interruptions in construction projects.

It's essential to inquire about the supplier's inventory tracking techniques,

current stock levels, and replenishment procedures to assess their capability

in meeting the requirements of your construction operations effectively.

Moreover,

fostering a robust and collaborative partnership with the selected dealer or

supplier is advantageous to facilitate seamless communication and streamlined

transactions. Transparent communication regarding precise requirements,

delivery timelines and potential concerns aids in averting misunderstandings

and guarantees the prompt and accurate delivery of spare parts. Additionally,

maintaining transparent lines of communication enables timely updates on

inventory status and any alterations or advancements that may affect construction

operations, ensuring adaptability and efficiency in project management.

Ultimately, collaborating with a dependable dealer or supplier capable of offering a diverse array of spare parts in one location and proficiently overseeing inventory can markedly boost the effectiveness and productivity of construction endeavors. Through diligent research and selection, construction firms can secure a reliable supplier, ensuring prompt access to necessary spare parts precisely when they are needed. This investment in identifying the right supplier not only aids in adhering to budgets and schedules but also plays a pivotal role in the successful execution of projects. Over, the availability of spare parts is paramount to the efficient operation of construction machinery, ensuring minimal downtime and maximum productivity on job sites.

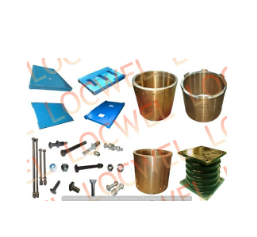

Locwel stands as

a reputable supplier of all the aforementioned spare parts in Delhi, offering a

comprehensive range of high-quality products to meet the diverse needs of

construction companies. With a commitment to excellence and customer

satisfaction, the company prides itself on providing top-notch filters for

Putzmeister concrete pumps, Flyash hoses, concrete hoses and cement hoses,

among other essential spare parts. Equipped with a well-managed inventory and

efficient logistics network, they ensure that construction companies have

access to the spare parts they need, precisely when they need them, thereby

minimizing downtime and maximizing productivity on job sites.

Comments

Post a Comment